Useful Bits & Pieces - Interfacing Aids

Contents

Introduction

This is just a short piece with our thoughts on what initial kit the newbie to this wonderful hobby of microcontrollers might think about acquiring. The variety of items now available at the local electronics shop and the huge online stores at prices that have become more attractive over the last decade can be overwhelming.

This is not going to cover the basic components of resistors, capacitors, transistors, diodes. LEDs and mechanical switches that are needed on an adhoc basis. These can be gotten from the local store as required or perhaps purchased in as kits from online.

The Essentials

There are some things that will be used on just about any microcontroller project. Being a subjective topic, not everyone will completely agree with our lists, but there still shouldn't be too many surprises.

This page is not meant as a tutorial in the use of these items. There's already many excellent online resources that do just that.

Breadboards

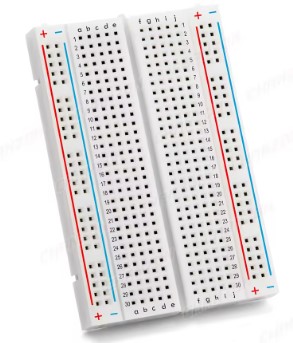

These allow the hobbyist to build solderless circuits for prototyping or just simply for learning pleasure. They come in a variety of sizes as shown in Fig 1. Most have power rails (+ve and -ve) along each long side. The smallest breadboards don't have this feature but are really useful for 'pinning' single breakout boards or chips.

Fig 1 - Breadboards most commonly available: 830, 400 and 170 tie points.

Essentially they are pegboards with spring loaded holes. Wires and pins are pushed into the holes with the internal springs holding them in place while providing good electrical connectivity.

Dupont Wires

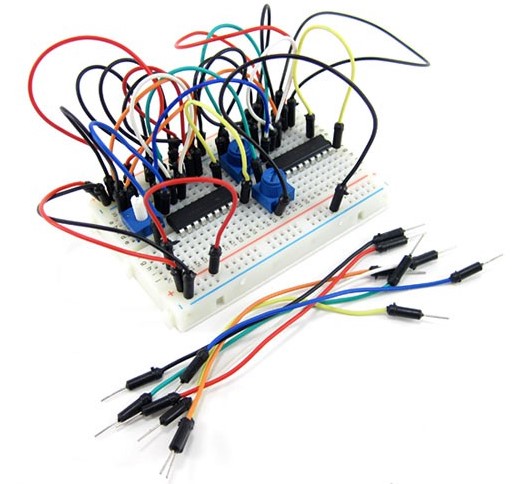

Dupont wires are specifically designed jumper wires for use in breadboards. The wires are typically available in various lengths and colors, with a choice of male-to-male, male-to-female, or female-to-female connectors at each end.

The male connectors are solid and strong for pushing into the holes of the breadboard. The female connectors provide connection to the pins of a microcontrollers or breakout board.

Fig 2 - [L] Bundle of Dupont wires, [R] Using Dupont wires on a breadboard[1]

Benchtop Mat

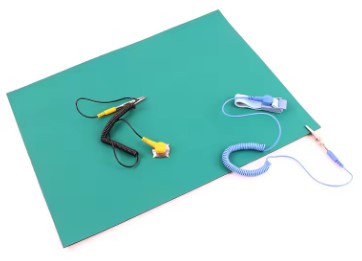

This leads onto another very handy accessory. Benchtop mats specially designed for electronic projects and repair jobs provide an ideal localised workspace for the project on the workbench.

.jpg)

Fig 3 - Antistatic benchtop mats

These mats, made from a rubberized compound with antistatic properties, are smooth to the feel but have non-slip surfaces. The mat is easy to pick up and relocate across a bench if space is needed temporarily for another task. This is a handy advantage of building the project on one of these mats.

Soldering Iron & Accessories

There is no avoiding it. Everyone eventually needs a soldering iron and then learn how to use it. For a start, most breakout boards are sold with header pins that require soldering to the board.

When it comes to the purchase of soldering irons this really is one of those cases where 'you get what you pay for'; hand over the money and get a good one!

Get the right soldering iron and soldering becomes a breeze - especially 'through the hole' soldering of header pins. The better soldering irons are thermostatically controlled with the user able to accurately set the tip temperature. They also come with a decent stand to sit the hot iron in while not in use.

Fig 4 - [L] Temperature controlled soldering iron, [R] Brass wire ball for tip cleaning

The iron's tip must be regularly wiped clean while soldering. In FIG 3 above, there is a yellow coloured sponge in the tray next to the control box. This is wet with water then can be used to clean the tip.

This is the old fashioned way of doing it. Unfortunately the water which is much cooler than the iron's tip will eventually destroy it. A much better cleaning aid is the brass wire ball shown in the RHS illustration of Fig 3. They work really well with one of these balls doing the job for many years - highly recommended.

Soldering iron tips (and solder) come in various sizes. For soldering header pins you will need a 1mm tip and 1mm diameter solder.

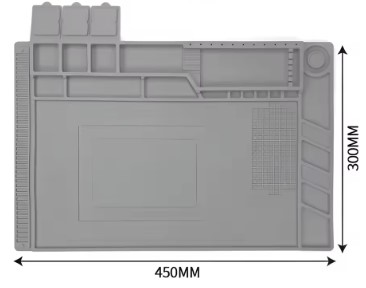

A 'must have' soldering accessory is the antistatic, heat-proof soldering mat. These don't just protect the workbench from being accidentally scorched but also protect delicate electronic components from static electricity.

Fig 5 - Heat resistant, silicone antistatic soldering mats

Another useful soldering accessory is the 'third hand'. While not absolutely essential they make life easier by firmly holding the solder job while solder and tip is applied. Many come with a largish low powered magnifier as well; very handy for those older eyes.

Fig 6 - 'Third hand' soldering aid.

Multimeters

Though some would argue that you can get by without a multimeter they sure can make life a lot easier. So, after some thought this humble tool ended up on our top list.

In recent years the digital multimeter has reduced in price and increased in functionality. Some now even incorporate an automatic mode; just put the probe tips across two points of the circuit or component and the meter will generally manage to work out what needs to be measured.

Fig 7 - Digital multimeters

The best modern multimeters can:

- Measure resistance (and continuity), voltage, current and temperature.

- Test diodes (including LEDs), capacitors and transistors.

- Count pulses.

The Importance of Good Housekeeping

This brings us to a another important point; housekeeping. As time marches on and the hobby becomes more and more engrossing the inventory of 'stuff' acquired will start adding up.

Here at fredscave.com the collection has grown to more than 140 different sensors (components, modules and breakout boards), all the usual collections of microcontrollers, basic components (resistors, potentiometers, capacitors, transistors, LEDs, mechanical/electrical/optical switches, etc), all sorts of electric motors, display units, input devices, and so and so.

When busy embarking on the new project the items on the "ingredient list" need to be readily sourced (and rapidly!) from the "big collection". We are severely space constrained which drove the need for a good storage system and an efficiently designed workspace.

Our housekeeping system is simple and has proven itself over time. Items are packed in plastic zip top bags including with antistatic material where necessary. Logical groupings of bags are stored in labelled (and numbered) ice cream containers (or the like).The containers are stored in a filing cabinet in numbered order.

Everything is logged in a spreadsheet which includes item name, description and storage container number. Even the most obscure component can be located in a matter of minutes. The spreadsheet is also used to log extensive note taking and has grown into quite a valuable resource.

Everyone has their own system, which is fine. Most won't be space constrained as we are here. Keep busy, keep learning and keep the workbench tidy!